Lost in Space: RedEye Brings Direct Digital Manufacturing Down to Earth

R2, your buddy in space (photo courtesy NASA)

Robonaut 2 (known as R2 to his friends) looks like the top half of an action superhero. Bulging biceps, massive pectorals, a helmeted head with an impassive gaze — certainly not a robot to be trifled with.

But R2 is a benign machine. Built and designed at NASA Johnson Space Center in Houston, Texas, this is a dexterous humanoid robot designed to help humans work and explore in space.

Dexterity is key. R2 has the ability to use the same space tools and work in the same environments as the astronauts. It can take over dangerous and repetitive tasks and perform them at skill levels exceeding those of a space suited human.

R2 was transported to the International Space Station (ISS) last February on space shuttle Discovery as part of the STS-133 mission. This was the first dexterous humanoid robot in space and the first US-built robot at the space station, a fact celebrated on the NASA website as "…one small step for a robot and one giant leap for robot-kind."

R2 is currently whirling around the earth on a fixed pedestal inside the ISS undergoing a full system check. Next steps include attaching a leg so it can climb through the corridors of the space station, followed by upgrades that will allow the robot to go out into the vacuum of space. Future models will sprout lower body appendages like legs and wheels for moving across Lunar and Martian terrain.

This one small step for robotics was a major step for direct digital manufacturing (DDM) and the use of fused deposition modeling (FDM). FDM is an additive manufacturing process that builds plastic parts layer by layer using data from CAD files.

Wyle's Integrated Science and Engineering Group in Houston helped NASA prepare R2 for launch to the space station. One of the company's responsibilities was to build a full-scale mockup of R2 for the simulation of potential missions. The mockup had to duplicate the geometry and appearance of the actual R2, and its limbs had to be easily moved into the same positions that the real robot would take during a mission. It also had to withstand rough handling during simulation and training exercises.

The geometry of the mockup was complex, time was short, and cost was, as always, an issue.

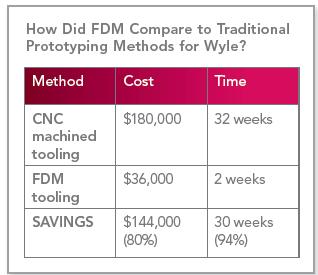

The use of traditional manufacturing techniques to create the mockup would have found it difficult to deal with the mockup's complex geometry. Also, thick parts would be needed to support the unit's movements. The estimated delivery time for conventional machining of the mockup was eight months at a cost of $180,000.

Enter RedEye, a Stratasys company, which uses advanced FDM techniques to produce prototype and end use parts on demand. Among the materials used by the company are high strength thermoplastic materials such as ABS (Acrylonitrile/Butadiene/Styrene). Wylie had already successfully used RedEye On Demand digital manufacturing services in a previous job and was happy with the results. So they sent CAD models to RedEye for a quotation and evaluated the mechanical properties of the FDM materials on the supplier's website. The upshot was that RedEye got the job, created all the parts needed for the mockup, and made both Wylie and NASA very happy with the results.

R2 mockup at the Johnson Space Center

The chart below shows the comparison between the traditional approach to the job and RedEye's FDM solution. In reality, there was no comparison.

FDM and Advanced Digital Manufacturing

The successful prototype of Robonaut 2 is one of numerous examples that indicate 3D printing technology has come of age. It has moved beyond just rapid prototyping. FDM is now being used for custom manufacturing, replacement parts, and low-volume production. As the technology evolves, it is increasingly competitive with traditional manufacturing practices such as injection molding.

Jeff Hanson, business development manger for RedEye, has been tracking the field since 2004, the year the company was founded and he came on board. Hanson also recalls that it was the year of the Iraq War's second battle of Fallujah.

Jeff Hanson, business development manger for RedEye, has been tracking the field since 2004, the year the company was founded and he came on board. Hanson also recalls that it was the year of the Iraq War's second battle of Fallujah.

"The US military asked RedEye to quickly produce the prototype of a flashlight to mount on the M16 assault rifles for city fighting," he says. "We 3D printed the prototype using ABS materials. It worked so well that the purchasing team asked us to go directly to the finished product using the same FDM technology and thermoplastics. That was an eye-opener. Up until then, we had looked at our technology as a solution for rapid prototyping only; now we understood we could use our FDM machines to produce parts for end use as well."

From Concept to Finished Product

Tackle box made of ABS engineering grade plastic

Today, Hanson says, the technology is used throughout the complete development cycle — from the concept phase and initial prototyping to functional and beta testing, including pilot tests in the field. And, in an increasing number of cases, FDM is used to manufacture finished parts for end use.

He compares this approach with the far more cumbersome and expensive traditional manufacturing processes, which includes creating the tools needed to make the parts, manufacturing the prototypes, testing them in the field, and then retooling to accommodate inevitable design changes. "You mitigate all that risk by using the FDM process," he says.

Single prototype created in a RedEye FDM machine

So, given its many advantages, why hasn't the additive approach to manufacturing using FDM technology totally supplanted more conventional approaches? Some of the challenges include an upper bound on the size of the product that can be produced, a limited range of thermoplastic materials, and the difficulty of making an object out of several different materials.

But the biggest hurdle to the widespread adoption of the technology, Hanson claims, is awareness. "One of our tasks is to educate the manufacturing market — especially the small to medium sized manufacturers — about the advantages of this technology. We have to let them know that FDM is no longer just used for rapid prototyping."

In order to validate its technology and services, RedEye has met a variety of certification standards including the ISO 9001 and AS9100. FDM is still a key technology for rapid prototyping, but increasingly it is being used to create finished products, especially for low volume, high end goods.

The Heart of the Matter

For example, a medical technology customer recently asked RedEye to create a concept model and prototype of a heart defibrillation tool. For this particular job, RedEye used thermoplastic materials that were FDA approved for surgical procedures. The DDM iterative prototyping helped the customer identity and fix design flaws early in the process, leading to clinical trials involving a pilot run of 250 units from RedEye.

The trials in turn uncovered other design modifications that needed to be made. At that point, due to the success of the prototyping process, the customer decided to abandon conventional tooling and use DDM throughout the rest of the manufacturing cycle to create the product for end use. With its FDM technology, RedEye manufactured 2500 defibrillator sets that were assembled, sterilized, shrink wrapped and put into the field. DDM helped the customer produce a better product for less cost, and bring it to market far more quickly than would have been possible with traditional manufacturing methods.

The Shoemaker's Children

When it comes to fostering awareness of the advantages of DDM, Scott Crump, RedEye CEO, candidly admits in a white paper posted to the company's website "We were not practicing what we preached."

When it comes to fostering awareness of the advantages of DDM, Scott Crump, RedEye CEO, candidly admits in a white paper posted to the company's website "We were not practicing what we preached."

Wrote Crump, "…within our own company we were resisting changes to established manufacturing processes. Sure, we had fully embraced our own technology for prototyping, but its limited use to manufacture parts for our new machines was frustrating.

"It should not have come as a surprise," he continued. "To some degree, every company struggles with change. While vital to progressive and aggressive companies, change can be difficult to facilitate. It seems that resistance to change grows along with the required effort or the perceived risk level. Add an aggressive deadline and no margin for error to the mix and the attitude becomes, 'If it ain't broke, don't fix it.' Without intervention, current practices can become standard processes that seem to be carved in stone.

"The solution to this dilemma was to change the mindset by taking action. For a recently released machine the design team was required to identify at least a few parts that could benefit from DDM and then apply it. The support of management diminished the risk of breaking from status quo while rewarding positive change. This tactic allowed designers and engineers to experience the benefits and possibilities of DDM. They saw sharp reductions in tooling costs, design constraints and manufacturing lead times.

"Our breakthrough came during the design of our newest highend system, the Fortus 900mc. As the machine began to take shape, there was a revelation among our engineers — a realization that DDM isn't just for our customers, but it is a practical and powerful solution for our design and manufacturing teams as well. The change in attitude was palpable. Designers and engineers that were skeptical became enthusiastic. At the start of the program, the engineering team earmarked only three components for DDM. By the time the first machine shipped, it included 32 production parts built via DDM."

Crump concludes, "There were numerous benefits realized in design, engineering and manufacturing, but many of them were immeasurable. Collectively, the benefits of DDM were much greater than the roughly $200,000 saved by eliminating tooling and machining."

DDM and the Future

Right now, RedEye is focused on providing components for high end, low volume products such as their own Fortus 3D production systems. But the landscape is rapidly changing.

"Today volume is the dictator," comments Hanson. "Currently it makes more sense economically to handle concept, design, rapid prototyping and short manufacturing runs using DDM and employ traditional injection molding for longer runs. But the relationship between the two methods of manufacturing is shifting. DDM will not replace traditional manufacturing — it complements it. As DDM technology evolves, along with advances in cloud computing and networking, you're going to see an increasing volume of end use parts with complex geometries being produced using the FDM process."

Hanson notes that small to medium sized manufacturing (SMM) companies make up a good percentage of RedEye's customer base, a trend he expects to continue.

"These companies are constantly looking for ways to cut costs, reduce risk, and bring products to market more quickly, he says. "SMMs are the early adopters of our technology."