HPC, the Cloud, and Help for the Missing Middle

Digital manufacturing in the cloud is a key element in the empowering of the “missing middle.” Cloud services can bring advanced technologies – such as modeling and simulation – to small and medium sized manufacturers (SMMs) that previously were unable to take advantage of these technologies because of cost, infrastructure shortcomings, and lack of expertise.

Says Jon Riley, Vice President, Digital Manufacturing at the National Center for Manufacturing Sciences, “While awareness and culture are two formidable barriers to the adoption of digital technologies in our nation’s small and medium sized manufacturers, the number one challenge remains the up-front investment in both capital and personnel required compared to the perceived value these tools will bring. As with any business it is a simple question of ROI. Cloud computing addresses this critical challenge by significantly reducing software costs as you move from node locked licenses to a smaller pool of shared licenses; consolidating IT systems in the cloud enabling more efficient and cost effective to maintain; and increased off-site productivity. These three dimensions of cost savings are enabling many manufacturers to experience a competitiveness boom.”

A Vendor Viewpoint

One example of a major vendor bringing cloud services to the SMMs is Autodesk, known for its venerable AutoCAD software that has been supporting computer aided design and drafting since 1982.

Recently the company has be en developing its cloud offerings to bring enhanced CAD capabilities to a wide variety of customers, including SMMs.

en developing its cloud offerings to bring enhanced CAD capabilities to a wide variety of customers, including SMMs.

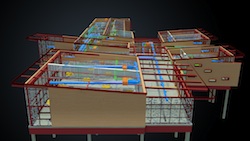

Andrew Anagnost, Autodesk Vice President, Suites and Web Services, points to the use of cloud services in conjunction with the Autodesk Building Information Modeling (BIM) portfolio as a good example of how smaller companies can be provided access advanced manufacturing technology.

Anagnost says that Autodesk is using the cloud as a natural extension of its customers’ current tools and workflows – moving into the cloud does not represent a major disruption of current practices. “What our approach does do,” he notes, “is empower and connect you to the design community and connect you and your data to powerful design services. This approach allows you and your colleagues to connect with the relevant data from any location using any device including smart phones and tablets.”

Moving the Autodesk BIM portfolio in to the cloud was announced at Autodesk University, held in Las Vegas last November. The idea is to provide AEC (Architecture, Engineering, Construction) project teams with the collaborative and data management tools required to streamline complex product and business processes. This includes working directly with Autodesk products such as AutoCAD or Revit and with mobile devices like Android and Apple smartphones and tablets. It means being able to access extensive viewing and visualization capabilities, as well as the tools AEC project team members need to collaborate without regard to geography and the size of the data files that need to be shared.

Anagnost adds that the use of simulation to optimize the part or structure being designed is another important capability of the system. “With the flexibility of the cloud and the ability to quickly and easily run a large number of simulations, the designer can try out a variety of solutions before deciding on the final configuration. Once the component is optimized, the 3D CAD file can then be sent to a 3D printing service that is integrated with the cloud for rapid prototyping.”

Anagnost adds that the use of simulation to optimize the part or structure being designed is another important capability of the system. “With the flexibility of the cloud and the ability to quickly and easily run a large number of simulations, the designer can try out a variety of solutions before deciding on the final configuration. Once the component is optimized, the 3D CAD file can then be sent to a 3D printing service that is integrated with the cloud for rapid prototyping.”

The new system, currently called Autodesk Cloud, will become part of the Autodesk 360 portfolio of solutions. The intent is to allow AEC users to manage the whole BIM process through the cloud, exposing the data wherever needed and allowing people to make design decisions based on that data in an on-line, real time collaborative setting.

One of the capabilities that will be added to Autodesk 360 for BIM is the customization of large data files being shared in the cloud. For example, Anagnost explains, a structural engineer will have very different needs compared to an architect – the engineer will want to see the bones of the building, while the architect is interested in the space and lighting. Working through the cloud, each will be able to structure the data presentation to fit their particular needs.

For the small to medium sized AEC firms that make up architecture’s missing middle, the Autodesk approach allows them to make a successful foray into the world of digital manufacturing. In fact, if these firms are sophisticated enough to use the 3D visualization capabilities supplied by AutoCAD – and many of them are – they can enjoy a far richer interaction with their clients.

In addition to being able to explore a wide variety of design solutions, the Autodesk Design Review mobile capabilities built into the Autodesk Cloud allow the architect to go to the client’s home or building site armed with a tablet or even a smartphone, and, using AutoCAD WS, make edits and design changes on the spot.

In addition to being able to explore a wide variety of design solutions, the Autodesk Design Review mobile capabilities built into the Autodesk Cloud allow the architect to go to the client’s home or building site armed with a tablet or even a smartphone, and, using AutoCAD WS, make edits and design changes on the spot.

“If the client wants to see what the interior design would look like if you move a wall, you simply click ‘edit,’ move the wall, present the results in 3D, and then save the client’s request,” explains Anagnost. “Or if you’re on a building site and need to fabricate a structural element like a girder for a specific use, you can design the element and then immediately conduct optimization tests online using the finite element analysis (FEA) capabilities available through the cloud. You can quickly run a large number of simulations in the cloud and come up with the best answer – something that was impossible in the past when we were trading emails and PDFs with the client.”

Modeling and simulation (M&S) capabilities like FEA and computational fluid dynamics (CFD can not be only be offered through the cloud, but also simplified so non-experts can use the software. This allow SMMs that cannot afford the time, training and cost of developing their own in-house HPC infrastructure and expertise to take advantage of these important M&S tools as well as leverage the collaboration, visualization, and data management capabilities available in the cloud.

Another Viewpoint

And finally, to get another perspective on manufacturing in the cloud and its impact on the missing middle, we put the question to Earl Dodd, President of Ideas And Machines, Inc. and i3D Inc., a contributor to Digital Manufacturing Report, and the former CEO of the Rocky Mountain Computer Center which provides HPC cloud services to the region. Here’s his reply:

Digital Manufacturing In The Cloud—the Missing Model in the Missing Middle

The National Institute of Standards and Technology (NIST) definition of Cloud Computing defines it as "a model for enabling ubiquitous, convenient, on-demand network access to a shared pool of configurable computing resources (e.g., networks, servers, storage, applications and services) that can be rapidly provisioned and released with minimal management effort or service provider interaction." NIST defines three "service models," or types of service: Infrastructure as a Service (IaaS); Platform as a Service (PaaS); and Software as a Service (SaaS).

Yet NIST is missing a very important category between PaaS and SaaS: Modeling as a Service (MaaS).

Having the services capability to determine required data (input and output), parameters and calibration (e.g., formats, standards, attributes, units, etc.), with the resolution of software application issues (e.g., pedigree, accuracy, quality, security, interactivity, etc.), will accelerate the standardization and democratization processes for cloud services. MaaS leads to data, application model and visualization integration supporting the NIST Definition of cloud computing.

Data accessed and generated via MaaS, especially high performance computing (HPC) applications and those provided by independent software vendors (ISVs), will take advantage of this services paradigm. The critical meta-information exchange required to drive MaaS and related web portals, gateways and tools truly completes the cloud software stack. MaaS will become the “next enabler” driving cloud services for the “missing middle,” allowing the small- to medium-sized enterprises (SMEs) to transition into cloud-based solutions, including NIST's hybrid cloud model in which multiple cloud systems are connected in a way that allows applications (ISV and custom) and data to be moved easily from one deployment system to another.

Based on the comments by Jon Riley, the example of Autodesk, and Earl Dodd’s take on services and MaaS for the missing middle, it appears that the cloud has a bright future in manufacturing.