CFD on ORNL’s Titan Models Cleaner, High-Mileage ‘Opposed Piston’ Engine

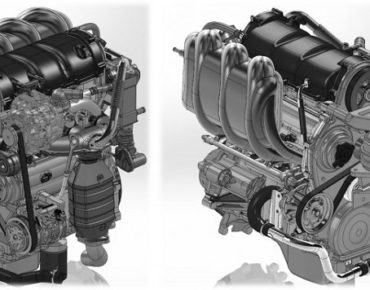

CAD models of the Pinnacle Engines opposed-piston gasoline engine

Pinnacle Engines is out to substantially improve vehicle gasoline efficiency and cut greenhouse gas emissions with a new motor based on an “opposed piston” design that the company hopes will be widely adopted while the global small vehicle industry transitions to a non-fossil fuel future, decades away.

To speed up work on its design – formally called a four-stroke, opposed-piston, sleeve-valve engine – Pinnacle turned to the HPC resources at the Leadership Computing Facility at Oak Ridge National Laboratory (ORNL), including the 27-petaflop Cray "Titan" supercomputer. After optimizing commercial Converge CFD software for Pinnacle’s technical needs and Titan’s architecture, the team ran thousands of simulations on Titan and on ORNL’s Eos 736-node Cray XC30 cluster. According to a blog posted by ORNL, the computational time totaled about six months, and Clayton Naber, Pinnacle’s lead analysis engineer, estimated it would have taken eight times longer had his team used Pinnacle’s in-house cluster.

“To do a really good job of characterizing the behavior of the engine through CFD, we would need about four years’ worth of raw computational time,” Naber said. “On Titan, we were able to compress that down into just a few months’ worth.”

Although the blog did not include estimated gas consumption and emissions reductions from the simulations run at Oak Ridge, early tests of Pinnacle motorcycle engines show a 33 percent improvement in gas mileage.

In Pinnacle’s opposed-piston design, “two pistons reciprocate in relation to each other instead of a cylinder head,” where heat can be lost, wasting energy, in a conventional reciprocating internal combustion engine, according to ORNL. The Pinnacle design cuts heat loss and enables a range of piston motions that can be used to increase efficiency.

Using Titan, the Pinnacle team simulated design options for a multi-cylinder, 1.2-liter gasoline engine. The specific engine optimization revealed by Pinnacle’s Titan simulations is what Pinnacle calls “swumble mode,” “a combination of swirling and tumbling gas in the combustion chamber,” according to ORNL. “The variable valve timing and compression ratio optimize combustion for different engine speeds and work outputs during engine operation by responsively moving the pistons to adjust the gas compression. The swumble mode reduces fuel usage and emissions at certain operating conditions by improving fuel and air mixing.”

Using Titan, the Pinnacle team simulated design options for a multi-cylinder, 1.2-liter gasoline engine. The specific engine optimization revealed by Pinnacle’s Titan simulations is what Pinnacle calls “swumble mode,” “a combination of swirling and tumbling gas in the combustion chamber,” according to ORNL. “The variable valve timing and compression ratio optimize combustion for different engine speeds and work outputs during engine operation by responsively moving the pistons to adjust the gas compression. The swumble mode reduces fuel usage and emissions at certain operating conditions by improving fuel and air mixing.”

The company’s design also includes “a novel, reciprocating sleeve-valve system,” for exchanging fresh air and exhaust from the combustion chamber. “The timing and motion of the sleeve valves can be controlled to enhance air motion and fuel mixing, which improves combustion and reduces the creation of pollutant emissions,” according to ORNL.

Modeling all of this is, of course, highly complex.

“The primary issue we are faced with is the many degrees of freedom,” Naber said, “or the many variables, that impact both efficiency and exhaust emissions. It has been impractical to do these calculations on our in-house commercial computer cluster.”

Naber said before running simulations on Titan, “we had a partial view and some details about the air motion in the engine and how it affects combustion. But on Titan, we were able to run simulations to see what the flow field looks like at finer resolution and were, therefore, able to better understand it.”

Naber said before running simulations on Titan, “we had a partial view and some details about the air motion in the engine and how it affects combustion. But on Titan, we were able to run simulations to see what the flow field looks like at finer resolution and were, therefore, able to better understand it.”

The result: “Ultimately, we were able to find a design to achieve very low emissions while also maintaining high efficiency,” Naber said. “This was a design that we did not have prior to embarking on this project.”

Pinnacle gained access to Titan and the Cray cluster by applying through the DOE Small Business Vouchers program, which led to a collaboration with the DOE Vehicle Technologies Office and researchers at the National Transportation Research Center (NTRC) at ORNL.

Titan was built by Cray, uses a combination of GPUs and CPUs and became available to researchers in early 2013.

“The punchline is that we found a design that achieves diesel-like fuel efficiency without some of the more expensive after treatment equipment that diesel requires,” Naber said. “Through access to Titan and collaboration with NTRC researchers, we discovered a design concept that was able to achieve our technical goals of higher efficiency and lower nitrogen oxide emissions.”

Pinnacle now has moved to the next step: constructing a physical prototype of the engine for experimental testing.

“For us, it’s really about commercialization next,” Naber said.